- These proceedings concern alleged fire safety and electrical engineering defects in the basement power plant of the Oncology Centre (“the Oncology Centre”) at St James’ University Hospital, Leeds (“the Hospital”).

Factual background

- By a Deed dated 15 October 2004, St James’s Oncology SPC Limited (“Project Co”), entered into a Project Agreement with Leeds Teaching Hospitals NHS Trust (“the Trust”) under the Government’s Private Finance Initiative for the design, construction, operation and maintenance of the Oncology Centre as an extension to the Hospital (“the PFI Project”).

- Also on 15 October 2004, Project Co:

(1) appointed Lendlease Construction (Europe) Limited (“Lendlease”) to design and build the Oncology Centre (“the D&B Contract”) for a Base Contract Sum of over £173 million. Lendlease Construction Holdings (Europe) Limited (“Lendlease Europe”), Lendlease’s parent company, provided a guarantee (the “Parent Company Guarantee”) to Project Co in relation to Lendlease’s work on the Oncology Centre. Throughout this judgment the Defendants will be referred to collectively as “Lendlease”, save where the context dictates otherwise.

(2) entered into a contract with Engie Buildings Ltd (“Engie”) to carry out estate maintenance renewal and replacement services at the Oncology Centre over the 30 year lifetime of the PFI Project (the “EM Contract”).

(3) entered into a tri-partite agreement with Lendlease and Engie (the “Sub-Contractor Co-Operation Agreement”) setting out their respective obligations and liabilities, including how claims and liabilities were to be resolved and/or re-allocated between them. In short, Project Co could require Engie to carry out remedial works and, if those remedial works related to defects caused by Lendlease, Engie was entitled to claim an indemnity for the cost of those works from Lendlease.

- Also by a Deed dated 15 October 2004, Lendlease engaged Faber Maunsell, now known as AECOM Limited (“AECOM”) as its mechanical and electrical design and building services consultants to carry out services in connection with the PFI Project. AECOM was the lead consultant responsible for designing the fire strategy for the Oncology Centre. Anshen Dyer were engaged to provide architectural services (“the Architect”).

- Lendlease commenced its works under the D&B Contract in 2004 (“the Works”).

- The Oncology Centre, which is located in the Bexley wing of the Hospital, is the largest oncology centre in the north of England. It contains 13 levels and has an approximate floor area of 67,300m2 with 2400 rooms in total and beds for 350 in-patients spread across 14 wards. Its facilities include 4 operating theatres, an intensive care unit (“ICU”), a high dependency unit (“HDU”), bunkers for radiotherapy treatment, brachytherapy, chemotherapy, imaging and radiology departments, research facilities and pharmacies. Many of these facilities use medical equipment and machines which require an electricity supply.

- Pursuant to the contractual arrangements referred to above, the Oncology Centre is now operated by Project Co and maintained by Engie. Albany SPC Ltd (“Albany”) provides Project Co with management services covering the operational side of running the Oncology Centre, including resolution of disputes with contractual counterparties.

Plant Room 2

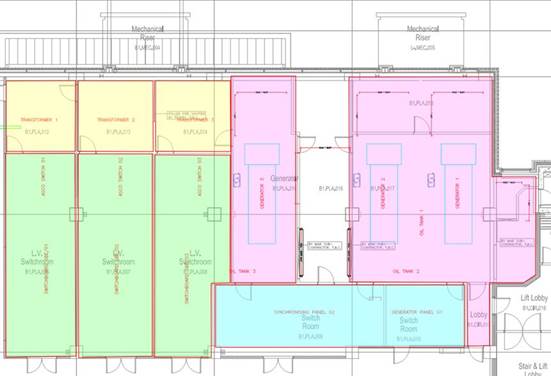

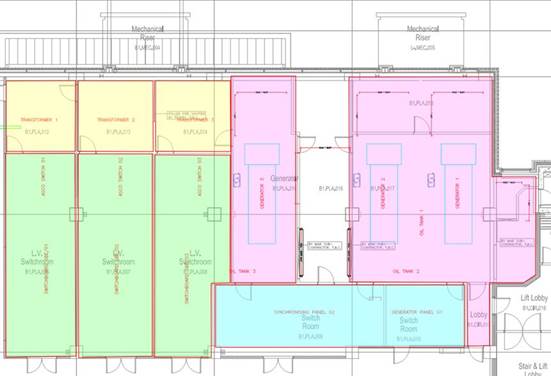

- Plant Room 2, located on basement level -1 (“B1”), is the central electrical and mechanical hub for the Oncology Centre. It contains many different items of building services equipment (plant) connected to building services distribution systems, such as pipes, cables and ventilation ducts. Within Plant Room 2 there are a number of electrical plant rooms which provide the electricity supply for all of the medical equipment and facilities in the Oncology Centre. The drawing below identifies specifically those electrical plant rooms (referred to as “the Electrical Substation”) in the coloured sections.

- The Electrical Substation comprises three High Voltage (HV)/Low Voltage (LV) transformer (TX) rooms (marked in yellow and labelled 1 to 3), three Low Voltage (LV) Switchrooms (marked in green and labelled 1 to 3), two generator rooms containing three generators (two in one room and one in the other) with their associated day-fuel tanks (marked in pink with the generators labelled 1 to 3) and two generator LV Switchrooms (marked in blue and labelled 1 and 2). Two mechanical risers are located on the external wall of the Electrical Substation.

- The normal running of the Electrical Substation can be summarised as follows:

(1) Electricity enters the building in the yellow section of the drawing from the external network at 11,000 volts (a HV supply) via two incoming HV cables which are connected to ring main units (“RMUs”) feeding the three transformers which are contained in white transformer cabinets.

(2) The three transformers reduce the 11,000 volts to 400 volts (a LV supply) so that it can be distributed throughout the Oncology Centre. This is the “primary” power supply. Each transformer is designed to accommodate approximately 50% of the Oncology Centre’s required load such that if one transformer fails, the adjacent transformer will be able to ramp up to take on the failed transformer’s load (via an automatic switch in the Switchboard).

(3) The three generators in the pink section of the drawing are not connected to the external electrical network, but are designed as a back-up (or “secondary” power supply) in the event that the electrical supply from the transformers is lost. They are designed so that two generators have the capacity to provide 100% of the electrical load required to power the Oncology Centre. The generators are diesel powered and sit next to the fuel tanks that supply them. Electricity from the generators is fed into the generator switchpanels (located in the blue section of the drawing), which in turn distribute the power to the LV Switchboards.

(4) The distribution of LV electricity around the Oncology Centre (whether from the transformers or the generators) occurs via the LV Switchboards located in the green section of the drawing. The cables from the LV Switchgear are routed on a cable management system at high level on ladder racks and cable trays.

Design Specifications

- Schedule 8 of the Project Agreement set out the Trust’s construction requirements for the Oncology Centre, including the “minimum technical and construction design standards”. I return to the detailed contractual provisions and design specifications in more detail in a moment, but of particular importance in the context of this case are:

(1) Health Technical Memorandum (“HTM”) 81 which provides guidance on the design of fire precautions in new hospitals and major extensions to existing hospitals;

(2) HTM 2007 which focuses on the design and operation requirements of electrical services supply and distribution in all types of healthcare premises;

(3) HTM 2011 which deals specifically with emergency and essential electrical supply equipment in all types of health care and personal social services premises; and

(4) BS 7671:2001 ‘Requirements for Electrical Installations’, ‘IEE Wiring Regulations Sixteenth Edition’ (“BS 7671”), concerning requirements for electrical installations generally.

- The Project Agreement expressly provided that Project Co’s design should comply with the principles outlined in HTM 81 and, in instances of non-compliance, those aspects of the design should adopt a justified fire-engineering approach and be to a standard equal to, or better than, HTM 81.

- The key document setting out the Oncology Centre’s fire-safety design is the Fire Safety Strategy prepared by AECOM. Fire strategy documents are used by designers as a means of explaining and justifying their fire safety design decisions to the end-user of the building.

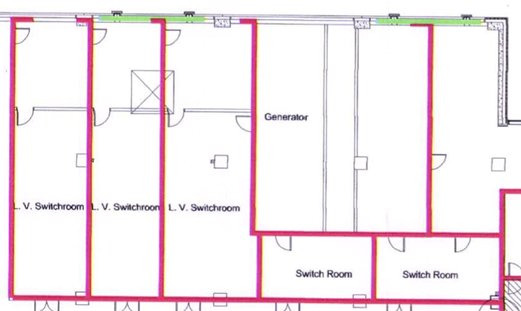

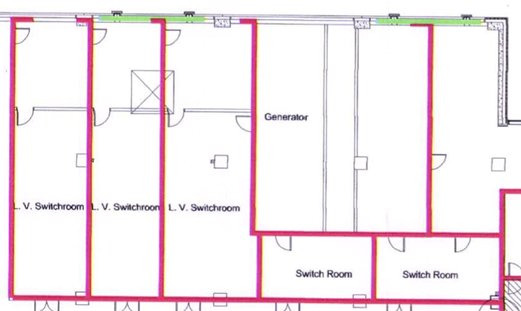

- Revision 12 of the Fire Strategy (the “Rev 12 Fire Strategy”) was expressly incorporated into the Project Agreement pursuant to Volume 7(6) of Part 4 of Schedule 8. It provided for 60 minutes’ fire compartmentation around the Electricity Substation and rooms within it, separating in particular each of the HV/LV Switchrooms, one of the generators from the other two and the generator control panels. This planned compartmentation is shown in the drawing below (red lines identifying 60 minute compartments and green lines identifying 120 minute enclosures with 60 minute doors):

- Revision 19 of the Fire Strategy (the “Rev 19 Fire Strategy”) is dated 19th November 2007, shortly before practical completion of the Oncology Centre. Importantly, by way of track change amendments to the text of the Rev 19 Fire Strategy, the need for compartmentation around the generators was removed. Furthermore the attached Architect’s drawing (Low-A-4200-B1-501 Rev E04 dated 20 November 2007) made clear that the whole of Plant Room 2 (of which the Electricity Substation formed only a part) was now a single fire compartment comprising an area of 1927m2. The Electricity Substation was no longer protected by fire compartmentation from the rest of Plant Room 2 and the individual rooms within the Electricity Substation were no longer separated from each other with fire compartmentation.

- As built, Plant Room 2 includes two different types of dividing partition walls. Those between rooms LV1, LV2 and LV3 and rooms TX1, TX2 and TX3 are formed as conventional plasterboard stud walls. These walls are formed to full height but mechanical and electrical services pass through the walls at a high level. The services pass through formed ‘letterbox’ openings in the partition walls which are larger than the services passing through. The openings are not sealed in any manner. The partition walls dividing rooms TX1, TX2, and TX3 from LV1, LV2 and LV3 and dividing LV3 from the generator rooms and dividing the generator rooms from the larger area of Plant Room 2 are fire rated lightweight partition walls. These walls are also formed to full height but again include openings at a high level for services to pass through. Again these openings are not sealed in any manner.

The identification of the Defects

- Practical Completion was certified on 14 December 2007.

- Between 2010 and 2014 annual PFI Statements of Fire Safety Compliance were signed by PJ Clark of Albany. Notwithstanding the apparently clean bill of health provided by these statements, deficiencies relating to fire stopping were identified in the Oncology Centre in 2014 following risk assessments and other works. These deficiencies were raised with the Trust and Project Co as an issue that needed investigation.

- Accordingly, Project Co engaged Hughes & Associates to report on the fire safety of the Oncology Centre. Hughes & Associates produced a “Fire Compartment Survey Report” in September 2014 based on a sample area of the Oncology Centre, identifying around 250 defects. Further to that report, additional defects were identified and remedial works were commenced. The remedial works, which were carried out by Lendlease between 2015 and 2017, did not concern any of the defects about which complaint is made in these proceedings.

- During the course of the remedial works, concerns were raised about the fire compartmentation within Plant Room 2. On 18 February 2015 Lendlease completed a “Reported Defect Initial Checklist” in respect of the Plant Room 2 walls.

- On 17 October 2017 Marcus Picken, of Albany, wrote to Alan Avey (“Mr Avey”), a Commercial Director of Lendlease, noting that a concern had been raised about the lack of sub-compartmentation between the switch rooms and generator rooms in Plant Room 2. Mr Avey responded on 23 November 2017 stating that the issue had been reviewed in 2015 and that Plant Room 2 had been built in accordance with the Rev 19 Fire Strategy.

- On 31 May 2018 an email from Les Bekesi (“Mr Bekesi”) of Lendlease to Mr Avey recognised that no sprinkler system had been installed in Plant Room 2.

- A further report (“Fire Door and Compartment Line Survey”) was provided by Hughes & Associates on 31 July 2018 (“the 2018 Hughes Report”), dealing with Plant Room 2. The 2018 Hughes Report concluded that remedial works were necessary based on the inadequacies of the Rev 19 Fire Strategy:

“The changes to the original approved Autumn fire strategy have resulted in current arrangements not adequately controlling the risk of the spread of fire. The plantroom, fuel stores, oxygen stores and HV equipment are all within one compartment under a tall building with openly ventilated walls to the exterior. The risk of fire spread horizontally and vertically is higher than would normally be acceptable in a fire risk assessment. The risk of losing power supplies, both primary and secondary, in a fire emergency is also too great to allow through risk assessment.”

- In circumstances where Hughes & Associates took the view that the existing ‘as built’ situation “has not been fire engineered, nor could a fire engineering argument be made for the current situation”, the 2018 Hughes Report recommended that the originally planned fire compartmentation should be constructed in Plant Room 2.

- The 2018 Hughes Report was sent to the Trust under cover of a letter from Mr James Lassiter (“Mr Lassiter”) on behalf of Project Co dated 7 August 2018 stating that, as the Trust was aware, Project Co had become concerned regarding fire safety within Plant Room 2 on level B1 at the Hospital and that, in the circumstances, a report had been commissioned. The letter referred to the fact that the 2018 Hughes Report had also been sent to Lendlease and it confirmed that the Trust would be kept appraised of developments.

- Project Co subsequently obtained a report from consulting engineers, Hoare Lea LLP (“Hoare Lea”), entitled “Evaluation of main substation installation fire compartment and electrical system review Revision 0” on 23 October 2018 (“the Hoare Lea Report”). Hoare Lea was asked to review the existing installation and issues identified by Hughes & Associates, with particular attention given to the lack of separation between the primary and secondary sources of electrical power. The Hoare Lea Report identified its scope as follows:

“Concerns about the integrity of the electrical supply were initially identified by SJO during the testing of the standby generators when it was observed that there was an apparent lack of fire stopping and separation. As an initial response to the concerns Hughes Associates were commissioned to provide a fire engineering report for the plantroom 2 area which concludes that the current arrangements do not adequately control the risk of spread of fire. This report provides additional information, in particular, with respect to the electrical installation in relation to the concerns raised by Hughes Associates.”

- Following the Hoare Lea Report, Hoare Lea was tasked with devising and refining a suitable remedial scheme. At the same time, Project Co commissioned Quadriga Health and Safety Ltd (“Quadriga”) to advise on the health and safety implications resulting from the defects identified. Quadriga’s initial report was provided on 21 July 2020.

- Hoare Lea produced an outline remedial scheme design on 23 November 2021 (“the Proposed Remedial Works”).

The Proceedings against Lendlease

- On 11 December 2019 these proceedings were commenced against Lendlease. Particulars of Claim were served, following an extension, on 29 June 2020 (since amended on 16 February 2022).

- In summary, Project Co contends that the construction of the Oncology Centre is defective in that it was built in breach of fire safety standards and contractual requirements. The defects on which Project Co relies are set out in a Scott Schedule to the Particulars of Claim which, as at the date of trial, identified 9 main defects with a total quantum of £6,242,274.47.

- These defects broadly concern fire safety and electrical engineering defects in Plant Room 2 and (with the exception of defect 2 which was abandoned by Project Co in opening) may be briefly described as follows (“the Defects”):

(1) Defect 1 - Plant Room 2 is a single fire compartment containing the Electricity Substation. There is no fire separation between any of the equipment/plant within Plant Room 2, where services pass through intermediate walls, the fire stopping is defective and the power supply cabling is not separately/diversely routed so as to reduce the risk of fire affecting both the primary and secondary power supplies;

i. Defect 1A - The installation of the transformers and generators is defective, in that they are not individually enclosed within 120 minute fire resistant construction so as to prevent fire spreading to other equipment. Further, as a consequence of Defect 1, there is inadequate protection to power supplies to the fire-fighting lift;

ii. Defect 1B - As a consequence of Defect 1, there is inadequate protection to the power supply for smoke extract fans within Plant Room 2;

iii. Defect 1C - as a consequence of Defect 1, there is no fire separation between the individual generators within the generator room, the generator room and adjacent LV switch rooms, and the remainder of Plant Room 2;

(2) Defect 3 - there is inadequate fire-stopping construction between the main electrical switchgear and “normal dependency” patient access areas. Further, Plant Room 2 does not have its own fire suppression system;

(3) Defect 4 - the service risers from Plant Room 2 do not constitute 120 minute fire-protected shafts and ductwork has been routed through the transformer rooms and into the service risers without any fire protection;

(4) Defect 5 - the route for the removal and renewal of the transformers and RMUs from Plant Room 2 is impractical and inadequate;

(5) Defect 6 - the route for the removal of the individual generators from Plant Room 2 is impractical and inadequate;

(6) Defect 7 - the ductwork in the rooms within the Electricity Substation leading from the air handling units through to risers up the building is not adequately fire-stopped;

(7) Defect 8 - the main outgoing cable installations from the LV switch rooms are routed through the generator room and/or into the remainder of Plant Room 2 without any fire stopping/barriers; and

(8) Defect 9 - there is no differentiation or separation between essential and non-essential cables throughout the Oncology Centre.

- In its Amended Defence and at trial, Lendlease focused almost exclusively on the content of the Rev 19 Fire Strategy to contend that the final design of the Oncology Centre is not defective. It argued that, to the extent that any aspects of the design are not compliant with the requisite technical specifications as set out in the Project Agreement and D&B Contract, these were derogations which were identified, justified, and ultimately approved by all the relevant parties. I shall refer to this as the “Fire Strategy Defence”.

- Shortly before the trial, Lendlease acknowledged that there had been a failure to install a fire suppression system in Plant Room 2 (Defect 3) and that works were required to replace 3 cables in the smoke extract system (Defect 1B). The remedial works accepted as necessary by Lendlease, which involve the installation of a water mist suppression system and replacement of these 3 cables (together with appropriate add-ons), are valued by it at £489,210.

Remedial Works

- The Proposed Remedial Works are to be implemented in two stages:

(1) Stage 1 (“the Stage 1 Works”) comprises works to mitigate the alleged risk created by the lack of fire protection for the generators, the absence of fire separation between the generators and other areas of Plant Room 2 and the presence of the large volume of fuel stored within the generator rooms. This will be achieved by the installation of an external tank (“the Fuel Dump Tank”) that provides 60 minutes of fire resistance, dump lines from the existing fuel tanks within the generator rooms that permit fuel to be excavated into the external tank in the event of fire and the installation of a temporary external generator, supplying power via a fire proof cable installation that is segregated from other circuits. The temporary generator will not be retained once the Stage 2 permanent works have been carried out.

(2) Stage 2 (“the Stage 2 Works”) involves a permanent remedial scheme designed to rectify each of the Defects.

- Macfarlanes LLP, solicitors to Project Co, wrote to Shoosmiths LLP, solicitors for Lendlease, on 21 January 2022 providing disclosure in relation to the Stage 1 Works and making clear that further documents in respect of the procurement of such works would be disclosed as and when available.

- As at the date of trial no remedial works had been undertaken. Engie has been contracted to commence work on the installation of the Fuel Dump Tank on 30 May 2022 and I understand that the Fuel Dump Tank is to be delivered to the Oncology Centre on or around 30 June 2022 and craned into place.

- For the first time in the Amended Defence served on 17 March 2022, Lendlease alleged that Project Co did not intend to implement any remedial works, a point that it pursued in opening, together with a further suggestion that there was also no evidence of the Trust’s intentions and/or approval in relation to the Proposed Remedial Works. I shall need to consider these allegations in more detail later in this judgment.

The issues

- The parties agreed a list of issues at the PTR, which was expressly said to focus only on the main issues. The outstanding issues for determination following the trial (as identified in the agreed list of issues) are as follows:

Fire Strategy:

(1) Was the Fire Strategy discussed and/or reviewed and/or agreed and/or approved by the Trust and/or Project Co and/or Building Control?

(2) If so, to what extent and in what respects?

(3) Did the Fire Strategy adopt a fire engineering approach within the meaning of paragraph 11.3 of Part 3, Sub-Part D of Schedule 8 to the Project Agreement?

(4) Did the Fire Strategy provide a standard of fire safety equal to or better than that provided for in HTM 81?

(5) Did Lendlease carry out and complete the Works under the terms of the D&B Contract in accordance with the Fire Strategy?

(6) If the works were completed in accordance with the Fire Strategy, can it be said that nonetheless Lendlease was in breach of contract to Project Co and, if so, on what basis?

Defects 1, 1A, 1B, 1C, 3, 4, 5, 6, 7, 8 and 9:

(7) Do the Defects constitute breaches of contract by Lendlease?

(8) If so, what (if any) of the remedial works as pleaded by Project Co are necessary, practical and proportionate to rectify such alleged Defects?

(9) Have any remedial works been carried out?

(10) Does Project Co intend to carry out any remedial works and, if not, what is the relevance of any absence of intention?

(11) What quantum is Project Co entitled to recover from Lendlease and/or Lendlease Europe in respect of each of those alleged Defects?

- Attached to its closing submissions, Lendlease provided a further proposed list of issues (not agreed by Project Co) which contained various new issues that Lendlease considers to be appropriate questions for consideration. In his oral closing submissions, Mr Hickey KC, on behalf of Lendlease, clarified that the new issues “identify some of the things that will need to be considered”. Whilst Lendlease may be right that the main issues identified above encompass various sub-issues and questions which I shall need to determine in this judgment, I see no need to over-complicate matters by expanding the agreed list of main issues. Accordingly, with one exception, I shall address the agreed issues in turn, picking up, where appropriate and necessary, any additional issues or arguments raised by the parties in their submissions. The exception is issue (9) above (“Have any remedial works been carried out?”). It is common ground that as at the date of trial no remedial works have been carried out and Mr Hickey struck this issue through in his proposed list of issues. Accordingly there is no further need for me to address the point.

the evidence

Disclosure

- During the course of the trial, Lendlease suggested on various occasions (both in submissions and during cross examination) that Project Co had failed to disclose relevant documents including, in particular, documents evidencing the Trust’s intentions in relation to the conduct of the remedial works. This had not been an issue prior to trial, no issue had been pleaded as to the Trust’s intentions and no issue identified for disclosure in the agreed Disclosure Review Document. Indeed there had never been any complaint in respect of Project Co’s disclosure until exchange of written Opening Submissions.

- In an attempt to meet this criticism (about which it chose not to complain), Project Co disclosed a few additional documents, whilst at the same time providing the court with a comprehensive explanation in respect of disclosure in a letter from Macfarlanes LLP to the court dated 9 May 2022. In light of the content of this letter, I am satisfied that Project Co has satisfactorily complied with its disclosure obligations and that there are no proper grounds for criticism by Lendlease.

- During the trial two applications were made by Project Co for the admission of previously undisclosed evidence.

- The first application related to (i) the admission of the second witness statement of Mrs Eleanor Reiblein-Berridge (“Mrs Berridge”), a General Manager within Albany, to deal with the new allegation in the Amended Defence to the effect that Project Co had no intention of carrying out the Proposed Remedial Works; and (ii) the admission of a supplemental quantum report dealing with the cost of installing Lendlease’s proposed water mist suppression system (also pleaded for the first time in the Amended Defence). In circumstances where Lendlease did not ultimately object to this application, I granted it on the first day of the trial.

- The second application related to a note of a meeting between (amongst others) Project Co and the Trust held on 6 April 2022, detailing the plan for the Proposed Remedial Works, together with the steps required to procure and deliver those works. The possibility that minutes from working group meetings between Project Co and the Trust might exist came to light during Mrs Berridge’s cross-examination and Project Co immediately carried out a search for the same, providing this document under cover of a letter dated 10 May 2022. Again, Lendlease did not object to the admission of this document and I accordingly permitted Project Co to rely on it. In light of the content of the letter from Macfarlanes LLP dated 9 May 2022 to which I have already referred, I do not regard the late disclosure of this document as evidence of a failure on the part of Project Co to comply with its obligations. On the contrary, Project Co appears to me to have acted properly throughout the trial to ensure full compliance with its disclosure obligations.

The witness evidence

Approach to the Evidence

- In closing, Lendlease invited me to draw adverse inferences from the absence of factual witnesses that could potentially have been called by Project Co.

- It is common ground that it is open to the court to draw adverse inferences from the absence of a witness who might be expected to have material evidence to give on an issue, but who is not called by a party who might reasonably have been expected to call that witness, without any adequate reason being given for his or her absence. However, before the court can draw such an inference there must be a case to answer on the issue (see Wisniewski v Central Manchester Health Authority [1998] PIQR 324, per Brooke LJ at page 340).

- The Court of Appeal recently considered the authorities on inferences (including Wisniewski) in Mackenzie v Alcoa Manufacturing (Gb) Ltd [2019] EWCA Civ 2110 per Dingemans LJ at [43]-[50]. At [50] Dingemans LJ said:

“It seems therefore that it is possible to state the following propositions. First whether it is appropriate to draw an inference, and if it is appropriate to draw an inference the nature and extent of the inference, will depend on the facts of the particular case, see Shawe-Lincoln at paragraphs 81-82. Secondly silence or a failure to adduce relevant documents may convert evidence on the other side into proof, but that may depend on the explanation given for the absence of the witness or document, see Herrington at page 970G, Keefe at paragraph 19 and Petrodel at paragraph 44”.

- I shall return to the specific inferences I am invited to draw in a moment. For present purposes, I note, however, that Project Co rejects the suggestion that the court should draw any inferences. Instead, it invites the court to determine this case on the available evidence.

Factual Witnesses

- The parties called only one factual witness each. Neither witness had been involved in the Works and the relevance of their evidence was accordingly somewhat limited.

Mrs Berridge

- Project Co called Mrs Berridge who had signed two witness statements, the first dealing primarily with her role at the Oncology Centre, the approach of the Trust to the Proposed Remedial Works and the substance of a meeting held on 10 December 2019 (“the December Meeting”) which she attended; the second dealing with the allegation raised by Lendlease in its Amended Defence that Project Co has no intention of carrying out the Proposed Remedial Works.

- Mrs Berridge is a General Manager with Albany and, since April 2019, has acted as Project Co’s representative in its dealings with the Trust, Engie and Lendlease, together with any other contractors, sub-contractors and suppliers engaged by Project Co or otherwise undertaking work or providing services in relation to the Oncology Centre. Mrs Berridge’s role was formerly held by Mr Lassiter, who remains an employee with Albany, but is no longer involved.

- Upon taking on this role, Mrs Berridge became responsible for the management of this litigation, a task she has not previously had any experience of. However, during her oral evidence she made it clear that she had relied heavily on a team of legal and technical experts to deal with the issues in the case. Accordingly she had plainly not considered the documents on file in any detail and had apparently not considered the pleadings - she was unable to say who had checked the pleaded facts. She had also not been involved in making decisions about the documents to be sent to the experts assisting Project Co. Despite her role as litigation manager, most final decisions about the conduct of the litigation appear to have been taken by the Board of Project Co, with input from Project Co’s lawyers and the wider team of experts.

- I found Mrs Berridge to be a somewhat defensive witness, albeit that may have been a function of the fact that she was cross-examined by Mr Hickey, on behalf of Lendlease, on various issues with which she was either unfamiliar or only peripherally involved. Her first witness statement was extremely limited in its compass but Mr Selby KC, on behalf of Project Co, explained in closing, and I accept, that this is explicable by reference to the very limited nature of the factual dispute on the face of the pleadings and the requirements of the new Practice Direction as to the preparation of witness statements - a point which may also explain Mrs Berridge’s inability to answer some of the very general points put to her by Mr Hickey.

- Overall, Mrs Berridge (who does not have technical expertise) was unable to assist the Court on many of the issues which Mr Hickey sought to explore, including events that occurred prior to her appointment in April 2019. In so far as Mrs Berridge was able to give relevant evidence, I accept that she was an honest witness who was endeavouring to assist the court.

Mr Avey

- Lendlease called Mr Avey to give evidence relating to the period between 2016 and 2021. Mr Avey is a Commercial Director of Lendlease who deals with legacy issues on Lendlease projects and has day to day conduct of the dispute with Project Co. He was only able to give evidence about matters that have arisen since May 2016. He provided one witness statement.

- Mr Avey was a transparently honest witness. He made concessions immediately when appropriate and did not attempt to evade difficult questions. He answered in a straightforward and direct fashion. Though cross-examination revealed there to be an error in his witness statement over dates, I accept that this was a genuine mistake.

Absent Witnesses

- In closing, Mr Hickey made five specific points as to the failure on the part of Project Co to call witness evidence:

(1) First, that Project Co had not tendered any witnesses who are directors or employees of Project Co itself and who were involved in the original construction of the Oncology Centre, making the point that there had been no attempt to prove by witness evidence any of the breaches of contract alleged against Lendlease in respect of its performance of the D&B Contract;

(2) Second that Project Co did not call Mr Lassiter, who is still employed by Albany. Before Mrs Berridge assumed her role Mr Lassiter had plainly been involved in commissioning early investigations into alleged defects and in liaising with others over those defects. Mrs Berridge did not appear to have seen various documents that would have been available to him. She accepted that Mr Lassiter might have liaised with the Trust over whether it had agreed the Fire Strategy. Mrs Berridge confirmed in her oral evidence that she did not know of any reason why Mr Lassiter would not have been available to give evidence;

(3) Third that Project Co had not tendered any evidence from Hoare Lea to deal with its Proposed Remedial Works solution;

(4) Fourth that Project Co had not tendered any factual witness from the Trust to deal either with the question of whether the Rev 19 Fire Strategy was discussed, justified and approved, or with whether the Trust was aware of the recommendations from Hoare Lea as to the Proposed Remedial Works and intended to instruct that they be completed. In relation to this failure, Mr Hickey invited me to draw an adverse inference that representatives from the Trust had not been called “for fear about what they might actually say if put on the spot”. His submission was that the absence of the Trust “speaks volumes” about the credibility of Project Co’s case and that, at the very least, Project Co should have called the Trust Fire Officer to explain statements he appears to have made which might be said to undermine Project Co’s case, primarily because they suggest that the Trust does not consider there to be a significant fire safety risk by reason of the Defects. It was Mr Hickey’s contention that the Trust’s evidence may have been adverse to Project Co’s case and that the court should take that into account. It was also his contention that if documents existed which evidenced the Trust’s concerns about the Defects in Plant Room 2, those documents would have been produced; accordingly the court is entitled to infer that no such documents exist.

(5) Fifth, and related to the previous point, was Mr Hickey’s contention that Project Co had produced no evidence, whether from Mrs Berridge or anyone else, that Project Co has complied with its contractual obligation to notify the Trust of the existence of the Defects, that those Defects need to be remediated and that there is a risk from fire whilst the Defects remain in situ. In his oral closing, Mr Hickey invited me to draw an inference that Project Co had not in fact provided such notification, primarily because it does not genuinely believe there to be a significant fire safety risk, but instead is pursuing this litigation with a view to reducing so-called “business continuity” risks.

- Whilst Mr Hickey is right as to his first point, I do not attach any real significance to it. The breaches now alleged against Lendlease were not identified at the time of construction of the Oncology Centre and have only been identified some considerable time after Practical Completion. In the circumstances, it is unsurprising that Project Co has not sought to call any evidence as to Lendlease’s performance of the D&B Contract at the time. As Mr Selby pointed out in closing, Lendlease has similarly chosen not to call evidence from representatives at AECOM. Furthermore, there is no evidence to suggest that representatives of Project Co took part in any discussions around the amendments to the Fire Strategy and thus there could be no expectation that witnesses from Project Co would be called to deal with this issue and no adverse inference from the failure to call such witnesses.

- As for his second point, whilst it does appear that Mr Lassiter may have had relevant evidence to give and that he might conceivably have discussed issues relating to his understanding of the approval of the Rev 19 Fire Strategy by the Trust, the fact remains that he was not around at the time the Rev 19 Fire Strategy was in fact approved. Any evidence from him could only have addressed his understanding based on what he had been told and/or had seen in the documents long after the event and accordingly would have been of limited, if any, assistance. In any event, I did not understand Mr Hickey to be inviting me to draw any inference by reason of his absence. Again, a not dissimilar point was made by Mr Selby in relation to (i) the absence of Mr Bekesi, who plainly carried out investigations into this claim for Lendlease and was apparently present in court throughout the trial, and (ii) Mr Alistair Hendrie who attended the December Meeting on which Lendlease places considerable reliance. In my judgment however, this case must, as Mr Selby submits, be determined on the basis of the evidence available to the court.

- Mr Hickey’s third point does not take matters any further. The Proposed Remedial Works are fully documented at considerable length, albeit that I was not really shown any of the documents during the course of the trial. Lendlease’s experts barely addressed the Proposed Remedial Works and Mr Hickey barely cross examined Project Co’s experts on their analysis of those Proposed Remedial Works. I fail to see how the attendance of a witness from Hoare Lea would have made any real difference.

- Mr Hickey’s fourth and fifth points both involve a submission that I should draw an inference and so I need to deal with them in more detail when I come to consider the issues around the approval of the Rev 19 Fire Strategy and the intentions of the Trust to carry out the Proposed Remedial Works. However, for present purposes I observe that Project Co and the Trust are separate entities, that there is no property in a witness and that Lendlease was just as able as Project Co to approach the Trust to obtain evidence had it wished to do so. Indeed, in many ways it would have made far more sense for Lendlease to approach individuals at the Trust for evidence given the positive case that it is running to the effect that the Trust agreed to the Rev 19 Fire Strategy and is not now interested in carrying out the Proposed Remedial Works owing to the fact that it does not consider there to be a serious risk of fire by reason of the Defects. In closing Mr Selby pointed out (and I accept) that the Trust’s intentions had not been seriously in issue prior to the Amended Defence on 22 March 2022 and that the question of the Trust’s intentions does not even feature in the list of issues agreed by the parties for trial. The absence of any pleaded issue is obviously a relevant consideration in the context of an invitation to draw an inference.

Expert Evidence - Mechanical and Electrical Engineering

- Project Co called separate experts in the fields of electrical engineering and mechanical engineering. Lendlease called one expert to address both of these disciplines. All three experts met for the purposes of preparing a Joint Statement dated 10 December 2021.

Mr O’Mahony

- Mr Shaun O’Mahony, BEng (Hons), a Chartered Engineer and Managing Director of MEP Efficiency was instructed by Project Co to provide expert evidence in the field of electrical engineering. Mr O’Mahony is an electrical engineer with over 30 years’ experience of building service engineering in the construction industry and he is also employed by HKA, a leading global consultancy in risk mitigation and dispute resolution (“HKA”) as an expert witness in electrical engineering matters. He has previously advised on a broad range of electrical problems and defects in healthcare buildings similar to the Oncology Centre.

- Mr O’Mahony’s report dated 4 March 2022 sets out his understanding of the contract documents, the scope of the various technical standards referred to in the contract documents and applicable at the time, and addresses the question of compliance in relation to the issues of non fire-resisting construction (Defects 1 and 1C), fire protection to power supply for smoke extract fans (Defects 1A and 1B), lack of cable segregation/separation to fire protection (Defects 8 and 9) and removal and renewal of transformer services and generators (Defects 5 and 6). Mr O’Mahoney then comments on the reasonableness of aspects of the package of Proposed Remedial Works.

- During his relatively short cross examination by Mr Hickey, I formed the impression that Mr O’Mahony was genuinely trying to assist the court.

Mr McDonald

- Project Co engaged Mr Neil McDonald as its mechanical engineering expert. Mr McDonald is a chartered building services engineer, a member of the Chartered Institution of Building Services Engineers, a member of the Society of Public Health Engineers and a member of the Academy of Experts. He is also a Technical Director of HKA. Mr McDonald has worked as a design and project engineer, at various levels, within building services design consultancies between 1987 and 2016, when he joined HKA. He has experience of design, specification and inspection of building services systems for many applications within the NHS Estate, including new build and refurbishment projects.

- Mr McDonald’s report dated 4 March 2022 addresses the mechanical building services aspects of the Proposed Remedial Works and, in particular, non fire-resisting construction (Defect 1), generator installation (Defect 1C), separation of main electrical switchgear (Defect 3), service risers (Defect 4) and switchgear/transformer/generator rooms ductwork fire stopping (Defect 7). Mr McDonald did not carry out his own analysis in respect of remedial works that might be required; instead he was instructed to consider the Proposed Remedial Works identified by Hoare Lea and to provide an opinion as to the reasonableness of those works. His report does not address questions of liability.

- During closing, Mr Hickey criticised Mr McDonald for merely adopting the Proposed Remedial Works identified by Hoare Lea without any independent critical analysis. However, I reject this criticism. Whilst it is true that Mr McDonald was not instructed to start from scratch in identifying the required remedial works, he nevertheless plainly spent time analysing and considering the works proposed by Hoare Lea and carrying out his own assessments and calculations designed to determine the reasonableness of those works. Attached to his report are various Appendices which evidence this analysis, including (i) his analysis as to the generator air handling systems; (ii) his analysis of Lendlease’s design for transformer room ventilation; and (iii) his analysis of various technical factors within the remedial scheme documents. He was not challenged on any of these Appendices in cross examination.

- Regrettably, it did become clear during his evidence that Mr McDonald had not always taken care to comply with his duties as a CPR Part 35 independent expert in that he had not always sought to ensure a level playing field with Lendlease’s engineering expert, Mr Bradley. In particular, he did not inform Mr Bradley that he was carrying out analysis of the ventilation for the generators in Plant Room 2 and he did not immediately disclose to Mr Bradley the measurements that he obtained. Mr McDonald frankly conceded that he had failed to consider whether this analysis should be raised with Mr Bradley in the joint discussions between the experts that took place prior to finalisation of the Joint Statement and he admitted that Mr Bradley was first made aware of this work only when Mr McDonald’s report was served. Mr McDonald was ultimately forced to accept that this omission was not consistent with his duties as a Part 35 expert and that as an experienced expert, he should have known better.

- Notwithstanding this lapse (which did not, in this case, affect the overall quality of his evidence), I generally found Mr McDonald to be an honest witness, doing his best to assist the court. He came under further criticism from Mr Hickey for failing to take any steps to consider the water mist suppression system advanced by Lendlease as a viable remedial solution. However, in circumstances where Mr O’Mahony and Mr Davis had considered this potential solution and given that Mr McDonald’s evidence under cross examination was that while he had familiarity with gas suppression systems (and had opined on the reasonableness of quotations for such a system in his report) he had no direct experience of water mist systems, I regard this criticism as unfair. Lendlease’s own experts barely mentioned the proposal for a water mist system, much less did they take steps to examine its viability in any detail.

Mr Bradley

- Mr Paul Bradley, a partner of Troup Bywaters + Anders, a private partnership of electrical and mechanical engineers, was called as Lendlease’s mechanical and electrical engineering expert. He has substantial experience in contracting and consultancy in both the public and private sectors. His experience includes managing design projects in the UK and abroad, including hospital projects.

- Mr Bradley prepared two reports dated 13 March 2022 and 24 March 2022 respectively. His first report considers Lendlease’s contractual obligations and then goes on to deal with each of the Defects. It records that he had not been instructed to examine in any detail the Proposed Remedial Works prepared by Hoare Lea, albeit that he “suggests” that these are proposals to improve fire related services at the Oncology Centre rather than to remediate defects within the original installation. His supplemental report responds to various issues raised in Project Co’s expert reports (including its expert report on quantum) which had not previously been raised.

- As was clear from paragraph 4.1.16 of his main report, Mr Bradley’s evidence was heavily reliant upon the Rev 19 Fire Strategy containing an engineered solution which, whist derogating from the technical standards, had been agreed and approved by all relevant parties. This placed him in difficulty from time to time in responding to the questions raised in cross examination. Whilst he was generally trying to assist the court, it became apparent (i) that there were some areas of his report that were not as comprehensive as they might have been (by way of example, he had not sought to consider whether the fire suppression works proposed by Lendlease provided the most optimal solution or whether they would create the need for consequential works and he had not given any consideration to the detail of the Plant Replacement Strategy (“the PRS”) in the context of Defects 5 and 6); and (ii) that there were a couple of areas in his supplemental report on the subject of the Proposed Remedial Works which were not entirely accurate, had omitted reference to relevant evidence (including Appendices to Mr McDonald’s report), needed clarification and were capable of being misconstrued (as Mr Bradley accepted). For these reasons, I consider that I need to approach his evidence with a little care, testing its credibility against the evidence of the other experts.

Expert Evidence - Fire Engineering

- Each party called an expert in fire engineering. The fire experts prepared two Joint Statements dated 9 December 2021 and 3 March 2022 respectively. The key issue between them was the adequacy of the Rev 19 Fire Strategy.

Mr Davis

- Mr Jamie Davis, an experienced fire engineer and chartered building engineer with over 18 years’ experience in the fire safety industry, was instructed by Project Co to provide expert opinion in the field of fire safety engineering. Mr Davis is experienced in operational firefighting and incident command, fire safety regulation and enforcement and fire engineering consultation and design. He has a BEng in fire safety engineering and is a Member of the Institution of Fire Engineers, a Member of the Institute of Fire Safety Managers and a Chartered Member of the Chartered Association of Building Engineers. He is also an accredited fire risk assessor with the Institution of Fire Engineers and has been an accredited validator under the BAFE SP205 scheme. He is employed by HKA.

- Mr Davis has a wide range of experience in evaluating and assessing passive fire protection measures in buildings, including in hospitals and healthcare buildings. He has recently been appointed by the National Health Service to review the national fire safety guidance for the fire safety design and management of hospitals.

- Mr Davis prepared one report dated 4 March 2022 which highlighted the principles of fire safety design, relevant legislation and guidance, provided an overview of the general fire safety design approaches, addressed the fire engineering aspects of Defects 1, 1A, 1B, 1C, 3, 4, 7 and 8, provided an overarching opinion on the basis of design and construction and opined on the suitability of the Proposed Remedial Works from a fire engineering perspective. He did not give evidence in respect of Defects 5, 6 and 9.

- Mr Davis conducted a site visit of the Oncology Centre on 10 November 2021 and inspected Plant Room 2. He describes the purpose of his visit in his report as being to “ratify the reports” provided by Hoare Lea and to familiarise himself with the Plant Room 2 area in general.

- I am afraid that I found Mr Davis to be an overly combative witness. On occasions he appeared rather too keen to advocate Project Co’s case (sometimes prefacing his answers with the phrase “I suggest”), he did not always provide an answer to the questions he was asked and he sometimes appeared unwilling to make appropriate concessions.

- Furthermore, it became apparent that Mr Davis had not paid rigorous attention to his duties as an independent expert. In particular, he had been in direct contact with Mr Don Court, employed by Hoare Lea, but had failed to inform Lendlease’s expert, thereby failing to ensure a level playing field. Mr Davis admitted that he had had conversations with Mr Court but had failed to take any notes of those conversations. He had attended a site visit at the Oncology Centre where he had been taken around Plant Room 2 by Mr Court but he did not inform Lendlease’s experts of this visit and did not address the visit in his report. In closing, Mr Hickey described this as a “free flow of information” of the type identified in Dana UK Axle Ltd v Freudenberg [2021] EWHC 1413.

- Given that, in reality, there appears to be little between the fire experts (the only real issue being whether as a matter of fact the Rev 19 Fire Strategy adopted an agreed fire engineering solution), Mr Davis’ somewhat unfortunate approach to his evidence does not affect my overall views on the fire evidence in this case and Mr Hickey did not suggest that I should disregard Mr Davis’ evidence. Standing back, I have little doubt that although some of his evidence under cross examination was given with a view to persuasion, nevertheless Mr Davis was an experienced expert witness whose evidence was generally reliable. Nevertheless, once again, it is disappointing to see yet another expert over-stepping the mark in court and apparently forgetting the importance of his CPR Part 35 obligations.

Mr Jones

- Lendlease instructed Mr Chris Jones, a fire engineer with 18 years’ of international consulting and surveying experience in fire engineering, as its fire expert. Mr Jones has a BSc in Applied Science with Forensic Measurement, an MSc in Fire & Explosion Engineering and he is an Associate Member of the Institute of Fire Engineers.

- Mr Jones has worked on fire engineering solutions for a wide range of buildings both in the UK and abroad. He has experience of fire testing and the performance of materials in fire. He has written numerous fire strategies for buildings across sectors and of various sizes and complexities across his 18 year career. He is currently employed by OFR Consultants, a firm of independent fire and risk consultants, and is one of the office leads for Manchester.

- Mr Jones prepared one report dated 14 March 2022; its stated aim was to “review the adequacy and the design and construction at the time of construction” of the Oncology Centre. His opinion as identified in his short executive summary was that (i) in respect of Defect 3, an appropriate fire suppression system was required; (ii) the remaining allegations are not ‘defects’ because an engineering solution in respect of Plant Room 2 “was proposed and accepted by all stakeholders” - for this reason, the Fire Strategy was adequate.

- Mr Jones did not visit the Oncology Centre, but undertook a virtual walkthrough after he had issued his report.

- Broadly, I found Mr Jones to be an honest witness who was willing to make concessions and generally tried to assist the court. As with Mr Bradley, Mr Jones’ evidence was, however, heavily dependent upon the existence of an approved engineering solution to fire safety, even though he accepted that he had seen no justification for any such solution. The following exchanges in cross examination illustrate his position:

“Q. …your view is that the fire strategy, revision 19, was adequate on the basis that it was agreed by relevant parties at the time?

A. Correct”

…

Q…for you to be satisfied that this agreement was a sound basis underlying the fire strategy…you would want to know…or be satisfied that there had been this fire engineering approach presented to the relevant users before…giving their approval…?

A Yes…looking at the correspondence there does appear to have been communication to the effect of the changes that were made. What I haven’t seen is the QDR process or anything that happened before that. That informed building control, the trust, fire officer etcetera to agree to the changes.”

- Mr Jones accepted that he had drawn inferences from the available documents as to the agreement by relevant parties to the Fire Strategy but that he could not add anything by way of fire safety expertise to this.

- Notwithstanding Lendlease’s belated reliance upon the viability of a water mist suppression system, Mr Jones did not provide any evidence to support this case.

Expert Evidence - architecture

- Project Co called one expert to address architectural issues arising in the context of the Proposed Remedial Works. Lendlease chose not to call an expert in this discipline.

Mr Kavanagh

- Mr Bart Kavanagh, MA (Arch) LLM Dip Int Arb RIBA FCIArb MAE Chartered Architect and Technical Director of HKA, was instructed by Project Co. He is an architect with more than 40 years’ experience in the construction industry and, during that time, he has been involved in the design and construction of a wide variety of building types.

- Mr Kavanagh produced one report dated 4 March 2022 addressing matters relating to architectural items, specifically building fabric issues, arising in the context of the Proposed Remedial Works. Specifically, his report addresses (i) the reasonableness of building fabric proposals in Project Co’s outline remedial proposals arising under Defects 1, 1C, 3, 4, 7 and 8; and (ii) the implications on the internal and external fabric associated with plant replacement strategy (Defects 5 and 6).

- I formed the impression, on his very brief cross examination, that Mr Kavanagh was a straightforward witness and I accept his evidence insofar as it is relevant to the issues I must determine.

Expert Evidence - Quantum

- Each side relied upon the evidence of a quantity surveyor to assess quantum. The quantum experts produced two Joint Statements dated 10 December 2021 and 31 January 2022.

- In their first Joint Statement they assessed the Stage 2 Works that formed part of the Proposed Remedial Works as identified by Project Co, albeit that various aspects of their assessment expressly remained outstanding. Furthermore they sought to make a “preliminary apportionment” of the estimated remedial works costs to each of the Defects, an approach subsequently acknowledged by Project Co to have been erroneous.

- In their second Joint Statement, they again focussed only on the Stage 2 Works and continued to identify issues which remained outstanding for consideration between them. This time they undertook what they described as “an arbitrary allocation” of the estimated remedial works costs to each of the Defects, again an approach which Project Co accepts was of no real assistance.

- By the date of the trial, there was considerable agreement between the quantum experts, on a figures as figures basis.

Mr Finn

- Mr Matthew Finn, BSc (Hons) LLM, FCIArb, MCInstCES FCIOB FRICS MAE MEWI, Senior Managing Director (partner) of the Construction Disputes and Advisory Practice at Ankura Consulting (Europe) Limited, was called as Project Co’s quantum expert. Mr Finn has been practising as a quantity surveyor for some 19 years and has considerable expertise in relation to construction and engineering projects. During his career he has worked as a quantity surveyor for UK contractors on project delivery and he has been involved in large hospital projects and PFIs. Mr Finn is an accredited and practising member of the Academy of Experts.

- Mr Finn prepared one report dated 4 March 2022 in which he provided his detailed evaluation of the claim in the sum of £6,242,274.47, focusing on the main differences between the experts.

- Although Mr Finn was the subject of criticism from Mr Hickey in closing, I found him to be a helpful witness who appeared well aware of his obligations as an independent expert and his duty to the court. I formed the impression that his evidence was both well considered, and reasonable. In my judgment there was no real substance to suggestions from Mr Hickey that Mr Finn had failed to keep his opposite number abreast of all aspects of his investigations and analysis. Indeed, I accept Mr Finn’s evidence that he was in frequent communication with Mr Somerset, Lendlease’s quantum expert, and that he had tried to continue discussions with Mr Somerset following receipt of Mr Somerset’s supplemental report in advance of the trial.

- It was revealed in cross-examination that Mr Finn had not previously been shown a quotation from Engie for the compartmentation work, to which I shall return. I do not consider this to have a material impact on the quality of Mr Finn’s evidence and I accept his analysis of the Engie quote as being priced broadly in line with the conclusions reached by both experts.

- A significant proportion of Mr Finn’s cross-examination concerned discrepancies between the loss pleaded by Project Co in its original and amended statements of case and Mr Finn’s expert report. I did not find this line of questioning to be particularly helpful. Furthermore it was accepted in closing by Mr Selby that in so far as the figures in the statements of case (in particular in relation to Defects 5 and 6) had included some “extra over” to account for the uncertainty around the quantum at that time, any criticism was best directed at the legal team.

- In so far as the allocation of remedial works costs to individual Defects is concerned, Mr Finn adopts a new approach in his report, not foreshadowed in the Joint Statements, but now endorsed by Project Co, to which I shall return later.

- For the most part, I consider that the approach taken by Mr Finn to the quantification of Project Co’s claim was entirely reasonable. He used a mixture of SPONS adjusted rates and quotations to price each part of the remedial scheme. When quotations were used he obtained more than one so that comparisons could be made. His methodology is clearly set out and evidenced in numerous Appendices attached to his report. I shall return to the detail of it in due course.

Mr Somerset

- Mr Somerset, BSc LLB (Hons) FAE FRICS FCIArb MEWI FPD, a director of Somerset Consult, a firm of Chartered Surveyors, was Lendlease’s quantum expert. Since 1986, he has specialised in the commercial, contractual and financial management of construction projects and disputes. As an employee of consulting organisations, he has spent a substantial portion of his time working with contractors, usually in the context of considering, preparing and analysing claims. He is a Fellow of the Academy of Experts and has considerable experience in acting as an expert witness, usually in the context of considering and analysing claims and final accounts.

- Mr Somerset prepared a report dated 8 March 2022 together with a supplemental report dated 25 March 2022. Mr Somerset’s first, and main, report deals with the areas of difference that emerged over the course of expert meetings and discussions with Mr Finn. His assessment in his report of the value of the Proposed Remedial Works is £2,771,721.27. At the point of service of this report Mr Somerset records that he has not had the opportunity to consider or opine upon any positive case that Lendlease and their experts may advance. His supplemental report responds to various points raised in Mr Finn’s report, increases the level of his assessment to £3,120,159.18 and also addresses the quantum of the scope of the remedial works proposed by Lendlease, which he quantifies at £489,210.91.

- Mr Somerset was plainly an honest witness who was doing his best in his oral evidence to assist the court and was willing to make concessions where appropriate. However, for reasons to which I shall return, I consider that Mr Finn’s evidence on quantum is to be preferred.

Expert Evidence - Overarching observations

- I do not consider there to be anything in the complaint made by Lendlease that Project Co’s experts have merely taken the alleged existence of the Defects at face value. Each has visited the Oncology Centre and carried out his own inspections and evaluations. I am satisfied that they have each investigated the alleged Defects and satisfied themselves of their existence. That they have taken this approach appears to me to be amply borne out by (i) the fact that Defect 2 was abandoned prior to trial following consideration of the matter by Mr Davis who produced calculations and concluded that the specific aspect of the design of Plant Room 2 with which Defect 2 was concerned could be shown retrospectively to comply with the Applicable Standards; and (ii) Mr McDonald’s evidence in chief correcting paragraph 8.4.2 of his report dealing with required remedial works and identifying that two fire dampers he had previously identified as being necessary were not in fact required.

- Ultimately, the very real problem for Lendlease arising in respect of its expert evidence going to liability is the extent to which the credibility of that evidence is dependent upon Lendlease’s Fire Strategy Defence. The content of the Joint Statements and the numerous concessions made by Lendlease’s experts during their evidence made this abundantly clear.

- Before turning to consider the parties’ arguments as to the Fire Strategy in more detail, I must first set out the contractual framework governing their relations.

The Contractual Framework

The obligations of Lendlease

- While Lendlease is not a party to the Project Agreement, pursuant to clause 5.1 of the D&B Contract Lendlease assumed the obligations, risks, and liabilities of Project Co under the Project Agreement:

“The Contractor shall, save as otherwise expressly provided in this Contract, perform and assume as part of its obligations under this Contract Project Co's obligations, risks and liabilities under the Project Agreement, the Schedules to the Project Agreement and the other Project Documents, insofar as the same relate to design, construction, commissioning, testing and completion of the Building Contractor's Works (as if the same were expressly referred to herein as obligations, risks and liabilities of the Contractor mutatis mutandis)”

- The terms of the Project Agreement are therefore directly relevant to Lendlease and set out the obligations that Lendlease has assumed.

The Project Agreement

- Clause 5.2 (General Standards) of the Project Agreement provides that:

“Project Co shall at its own cost be solely responsible for procuring that the Project Operations are at all times performed:-

5.2.1 in so far as not in conflict with an express obligation of Project Co under this Agreement, or where in relation to a matter there is no express obligation or standard imposed on Project Co under this Agreement, in accordance with Good Industry Practice;

5.2.2 in a manner consistent with the Quality Plans;

5.2.3 in a manner that is not likely to be injurious to health or to cause damage to property;

5.2.4 in a manner consistent with the Trust discharging its statutory duties and other functions undertaken by it as the same may be notified to Project Co from time to time;

5.2.5 in compliance with all Laws and Consents […]; and

5.2.6 except to the extent expressly stated to the contrary in the Trust’s Construction Requirements or the Service Level Specifications, in compliance with all applicable NHS Requirements.”

- Schedule 1 to the Project Agreement defined:

(1) “Good Industry Practice” as “using standards, practices, methods and procedures conforming to the Law and exercising that degree of skill and care, diligence, prudence and foresight which would reasonably and ordinarily be expected from a skilled and experienced person engaged in a similar type of undertaking under the same or similar circumstances”;

(2) “NHS Requirements” in relation to the Works as “Health Building Notes and Health Technical Memoranda and such other requirements as are designated as NHS Requirements in the Trust's Construction Requirements”;

(3) “Trusts Construction Requirements” as “the requirements of the Trust set out or identified in Part 3 of Schedule 8 (Construction Matters) as amended from time to time in accordance with the terms of this Agreement”;

(4) “Project Co’s Proposals” as “the document at Part 4 of Schedule 8 (Construction Matters) as amended from time to time in accordance with clause 40 (Variation Procedure)”; and

(5) “Works” as “the design (including the preparation of all Design Data), construction, testing, commissioning and completion of the Facilities (other than the Equipment) (including any temporary works), the installation of Plant…”.

- Clause 17.1 (Overall Responsibility) of the Project Agreement provides that:

“Project Co shall carry out the Works:-

17.1.1 so as to procure satisfaction of the Trust’s Construction Requirements;

17.1.2 in accordance with Project Co’s Proposals; and

17.1.3 in accordance with the terms of this Agreement.

To avoid doubt, the obligations in clauses 17.1.1, 17.1.2 and 17.1.3 are independent obligations. In particular:-

17.1.4 the fact that Project Co has complied with Project Co’s Proposals shall not be a defence to an allegation that Project Co has not satisfied the Trust’s Construction Requirements; and

17.1.5 the fact that Project Co has satisfied the Trust’s Construction Requirements shall not be a defence to an allegation that Project Co has failed to comply with Project Co’s Proposals.”

- Clause 13.1 of the D&B Contract was in materially identical terms. Thus Project Co and Lendlease were both obliged to comply with the Trust’s Construction Requirements, Project Co’s Proposals, and the terms of the Project Agreement.

- Clause 17.2 (Design Responsibility) of the Project Agreement provides that:

“Project Co warrants that it has used, and will continue to use, the degree of skill and care in the design of the Facilities that would reasonably be expected of a competent professional designer experienced in carrying out design activities of a similar nature, scope and complexity to those comprised in the Works.”

- Part 3 of Schedule 8 to the Project Agreement sets out the Trust’s Construction Requirements, with its General Requirements to be found in Schedule 8, Part 3, Sub-Part C.

- Paragraph 2.14 (Minimum Technical And Construction Design Standards) of Part 3, Sub-Part C, sets out the technical standards to be complied with in the design and construction of the Oncology Centre:

“2.14.1 Project Co shall ensure that the Facilities comply with Good Industry Practice, NHS Requirements, relevant statutory requirements and required consents except where expressly excluded in Project Co’s Derogations Report, including but not limited to the following:

2.14.1.1 Building Regulations; England and Wales

2.14.1.2 Fire Authority and Hospital Fire Officer requirements and Fire safety requirements, including, but not limited to, Firecode (HTM 81 to 87);

[...]

2.14.1.4 Relevant British Standards, Codes of Practice, or equivalent European industry recognised standards;

[...]

2.14.1.6 Health Technical Memoranda (HTMs) in relation to Facilities in Sub-part D this schedule 8 Part 3;

[…]

“2.14.2 Where two or more of the above are applicable the higher standard shall be adopted.”

- Paragraph 3.2 (Minimum Architectural Standards) of Part 3, Sub-Part C, provides that:

“3.2.2 Project Co shall take full account of the following:

[…]

3.2.2.9 Health Technical Memoranda

[…]

3.2.3 Project Co shall design the Facilities to comply with the following:

[...]

3.2.3.2 The performance of components shall be as described in sections 1-3 inclusive of the following HTMs and their related appendices and references unless otherwise states elsewhere:

[...]

3.2.3.2.19 HTM 81-Fire Precautions in New Hospitals

3.2.3.2.20 HTM 86 - Fire Risk Assessment in Hospitals”

- Paragraph 3.8 (Handback & Residual Life Expectancy) of Part 3, Sub-Part C, provides that the Oncology Centre must be designed and built in such a way so as to make maintenance and replacement as convenient as possible:

“3.8.2.4 Materials and components forming part of the Facilities, which require maintenance and replacement within the life of the Facilities, must be selected, located and fixed in such a way as to minimise future inconvenience, disruptions and to avoid temporary closure of the Facilities”

- Paragraph 4.6 (Loadings and Structural Flexibility) of Part 3, Sub-Part C, provides that:

“4.6.6 Project Co shall include, within their design, provision for removal, replacement and upgrading of installed plant and equipment. As part of this element of design, a comprehensive replacement strategy shall be prepared for implementation. This strategy shall, wherever possible, consider how these works can be undertaken whilst minimizing disruption to the function of the completed Facility.”

- Paragraph 5 (Mechanical and Electrical Engineering Requirements), of Part 3, Sub-Part C sets out the applicable mechanical and electrical technical standards:

“5.1.1 Project Co shall in constructing the Facilities, comply with these Mechanical and Electrical Engineering Requirements. These requirements shall be read in conjunction with Schedule 8 Part 3; Sub-Part D - the Project Specific Requirements.

5.2 Minimum Engineering Standards

5.2.1 Project Co shall comply with the following:

5.2.1.1 BS 7671 (IEE Wiring Regulations);

[...]

5.2.1.7 British and European Harmonised Standards and Specifications and Codes of Practice;

5.2.1.8 Health Technical Memorandum, in accordance with 2.14;

[…]

5.3 Performance Standards

5.3.1 Project Co shall ensure that the services designs comply with current industry standards and shall comply, but not be limited by, the following codes:

5.3.1.1 Chartered Institution of Building Services Engineers (CIBSE) Guides;

5.3.1.2 The Institution of Electrical Engineers Wiring Regulations (BS 7671)

[...]

5.3.1.6 HTM 2007 Electrical services supply and distribution

[…]

5.3.1.8 HTM 2011 Emergency electrical services”

- Schedule 8, Part 3, Sub-Part D is concerned with the Trust’s “Project Specific Requirements”. Paragraph 11.3 of Part 3, Sub-Part D deals with the Fire Strategy to be prepared by Project Co and expressly contemplates the potential for Project Co’s designs to fall outside HTM 81:

“11.3 Fire Strategy

11.3.1 Project Co shall prepare Fire Strategy drawings that show the following information

11.3.1.1 The Position and fire rating of fire compartment and sub compartment walls, including cavity barriers if appropriate.

11.3.1.2 The fire resistance of elements of structure, walls, and doors.

11.3.1.3 The location of fire Hazard rooms.

11.3.1.4 Ventilation drawings including provisions for fire stopping.

11.3.1.5 The provision of fire alarm system to HTM 82 standard, including the location of actuation points, detectors, sounders and where appropriate, control panels.

11.3.1.6 The provision of an Emergency Lighting system to HTM 2011 standard showing location of emergency lighting luminaires.

11.3.1.7 Access and facilities for the fire Service (where appropriate).

11.3.1.8 The location of fire fighting equipment.

11.3.1.9 The positions of Signage and notices.

11.3.2 Where Project Co’s design is outside the strict interpretation of HTM 81, or Project Co proposes a different fire precautions philosophy, Project Co shall adopt a fire engineering approach.

11.3.3 The design shall comply with the requirements of Firecode, and incorporate the fire precautions principles outlined in HTM 81. Any areas of non-compliance should be identified and justified by a fire engineering approach to provide a standard equal to or better than HTM 81 in compliance with clause 1.7 of HTM 81 [...]” (emphasis added).

- Pausing there, it is an important part of Project Co’s case that wherever there was any deviation from HTM 81 in the design of the Fire Strategy, the Project Agreement required this to be identified in the Fire Strategy and expressly justified by a fire engineering approach.

- Paragraphs 11.24 and 11.25 of Part 3, Sub-Part D provides as follows:

“11.24 Low Voltage Distribution Network

11.24.1 A new Low Voltage switchroom shall be provided by Project Co, in accommodation adjoining the HV switchgear and transformers, which shall accommodate the main LV switchboards.

11.24.2 The LV boards shall have sets of bus bars interconnected by means of bus couplers switches, with bus bars being served from one of the transformers in adjoining accommodation for security of supply.

11.24.3 In the event of the failure of one the transformers, the live transformers can serve selective loads on the off line bus bars if so desired.

11.25 Standby Diesel Generators

11.25.1 In the event of failure of the electricity supply Project Co shall provide a standby service, made available from diesel generators located adjacent to the substation. On failure of the normal supply, the generators shall automatically start and feed all essential services via the changeover mechanism. Acoustic attenuators shall be installed to reduce generator noise levels. The Trust shall provide from their central store, via their existing ring main an oil supply to service the generators. All adaptation works in connection with the link for the New Oncology Wing shall be carried out by Project Co. ASCO switches shall be provided for synchronous no break connection for load testing. Alternatively full synchronising of generators may be provided.

11.25.2 In the unlikely event of one generating set not starting, the generator supply can be isolated, bus bar coupling switching can be closed and an alternative generating set can then be utilised to serve selective loads on both sets of essential bus bars if so desired.

11.25.3 The standby diesel sets shall be sized to supply both essential and non-essential services on the assumption that the bus coupler between essential and non-essential bars shall be closed.”

- ASCO is the manufacturer of closed transition switches, which switch the feed into each LV switchboard between primary and secondary supplies, as appropriate.

- Schedule 8, Part 3, Sub-Part F to the Project Agreement sets out the Trust’s “Non Clinical Specifications”, including

“16.4.2 Standby/Electrical Distribution

16.4.2.1 Project Co shall establish the electrical distribution system by the construction of 11000V substations in the basement plantrooms formed by the extension of the existing HV ring main system serving St James’s Hospital.

[…]

16.4.2.10 Project Co shall serve the Facilities by modifying the existing HT ring with a minimum of 2 No Transformers supported by standby diesel generators. ASCO automatic or similar load switching shall be provided to avoid loss of supply during testing periods. Full synchronous sets may be an option with full network analysis. Spare capacity shall be built into the design by Project Co to assist in future flexibility, i.e. 10% growth/ spare switches/ circuits.

16.4.2.11 Project Co shall ensure that electrical distribution shall consist of electrical risers through the Facilities with switchrooms in or adjacent cupboards serving a split distribution system of essential and non-essential services. However 100% standby cover is required on standby generators and flexibility of operation of switchgear is required to ensure system reliability.

16.4.2.12 Project Co shall ensure electrical integrity by the addition of UPS systems to each of the following:

Theatre power

ICU/ITU/HDU power

All similar areas with Life Support Equipment”

(emphasis added).